Hyundai Motor and Kia collaborate with Next Hydrogen to develop advanced alkaline water electrolysis system.

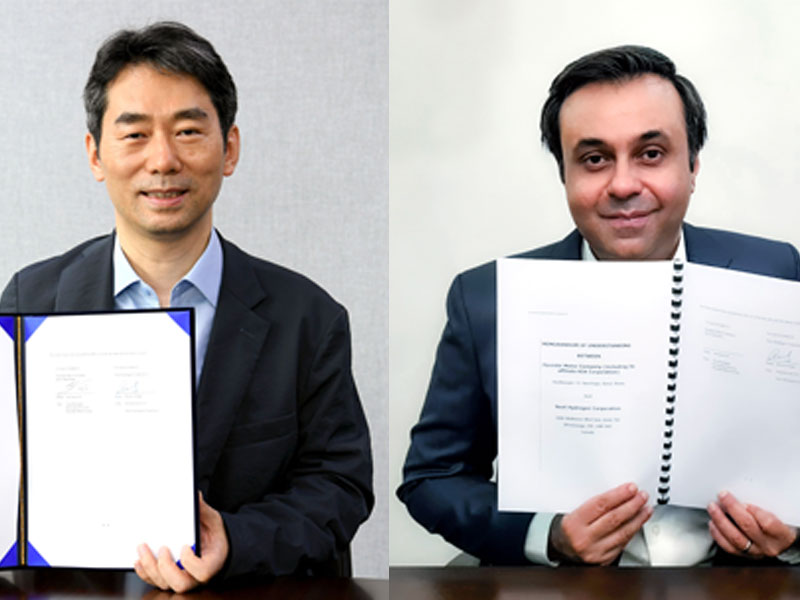

- Hyundai Motor, Kia and Next Hydrogen sign MOU to develop an advanced alkaline water electrolysis system that helps produce green hydrogen economically

- The companies aim to develop a more efficient stack for the system, and explore potential technological applications and commercial arrangements in the future

Hyundai Motor Company and Kia Corporation have signed a memorandum of understanding with Next Hydrogen Corporation, a Canadian company specialising in water electrolysis technology and a subsidiary of Next Hydrogen Solutions Inc., bolstering their efforts to usher in a global hydrogen society through cost-effective production of clean hydrogen.

Under the agreement, the companies will jointly develop an alkaline water electrolysis system1 and its related stack for the purpose of generating green hydrogen economically and exploring new business opportunities and technological applications.

Today it is expensive and time consuming to produce clean hydrogen. Due to this reason, Hyundai Motor, Kia, and Next Hydrogen are looking to improve the price competitiveness of clean hydrogen in consideration of regional climate and environmental characteristics. The companies, which are expanding their base by examining the strengths and weaknesses of various water electrolysis technologies, agreed to explore the possibility of alkaline water electrolysis system among various water electrolysis technologies this time.

Among the various methods of water electrolysis, the alkaline water electrolysis system is regarded as technologically one of the most rigorously tested and proven means with a long track record of research and development. Also, it has the advantage of being able to produce large-scale hydrogen and using relatively inexpensive catalysts, making facility costs low.

The aim is to advance stack-related technologies that are at the core of the alkaline water electrolysis system to reduce the cost of building the system and maintaining/operating the system. The key benefit to be derived from the project is that by enhancing the performance of stack-related technologies in the alkaline water electrolysis process, it will be possible to develop a new stack which can be operated at high current density2 and produce green hydrogen economically.

The newly developed stack will use Hyundai Motor and Kia’s component technology related to electrodes, bipolar plates and current collectors, combined with Next Hydrogen’s design technology. Hyundai Motor and Kia will also oversee the test performance of the new stack. A pilot test is planned for next year, and the companies will also explore potential technological applications and commercial arrangements.

“We are pleased to partner with Next Hydrogen specialising in state-of-the-art water electrolysis technology. This partnership is another leap forward for our hydrogen business and will be our first step into the alkaline water electrolysis market,” said Jae-Hyuk Oh, Vice President and Head of Energy Business Development Group at Hyundai Motor Group. “We believe our technology will be an excellent match for Next Hydrogen's technology, and this synergy will help achieve our goal to provide our customers with cost-effective green hydrogen.”

“Next Hydrogen’s innovative water electrolysis stack design technology is an ideal solution for enabling the economical production of green hydrogen,” said Raveel Afzaal, President and CEO of Next Hydrogen. “We are extremely appreciative of the opportunity to work with Hyundai Motor and Kia, given their industry leadership as champions of this technology. This partnership is expected to accelerate efforts to address the incredible emerging opportunities in sustainable transportation globally.”

Among the varieties of hydrogen produced by different methods, the conveniently called “green” hydrogen is one of the cleanest varieties, generating zero carbon emissions, as it is produced using water electrolysis powered by renewable energies such as offshore wind. Hailed as the “fuel of the future” for its eco-friendliness, green hydrogen has the potential to revolutionise the world’s industrial and transport sectors.

Apart from green hydrogen, the so-called “grey” hydrogen is made with fossil fuels and emit CO2 into the air as they combust, while the so-called “blue” hydrogen is produced the same way, but its carbon-capture technologies prevent CO2 from being released into the air and instead store carbon dioxide deep underground.

Due to high production costs, many hydrogen companies around the world are researching ways to advance their water electrolysis technologies for producing green hydrogen more economically. This common goal has brought Hyundai Motor Group and Next Hydrogen together to develop the technology as a more cost-efficient solution.

Hyundai Motor Group, the parent of Hyundai Motor and Kia, has recently introduced ‘HTWO’, a new brand representing the Group’s world-leading hydrogen fuel cell system. The Group is stepping up its efforts to develop a next-generation hydrogen fuel cell system that can be applied to various forms of mobility such as automobiles, vessels and trains and beyond.

Disclaimers.

1 Alkaline water electrolysis system: A hydrogen production method that electrolyzes water using an alkaline electrolyte such as potassium hydroxide (KOH) or sodium hydroxide (NaOH).

2 High current density:The more electricity available, the more hydrogen the alkaline water electrolysis system produces. Thus, an alkaline water electrolysis system equipped with a stack capable of carrying high current density can achieve higher economic efficiency by producing more hydrogen while taking up the same area.